Impregnating Resins Market Showing Impressive Growth during Forecast by 2030

Impregnating resins are a vital component in various industries, playing a crucial role in enhancing the performance and longevity of electrical and electronic components. These resins, often epoxy or polyurethane-based, are used to insulate, protect, and strengthen delicate parts, ensuring they can withstand harsh environmental conditions, temperature fluctuations, and mechanical stress. In this blog, we will delve into the Impregnating Resins Market, exploring its growth drivers, recent innovations, and emerging opportunities.

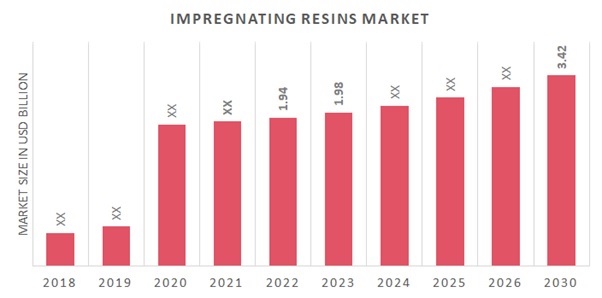

Impregnating Resins Market was valued at USD 1.94 billion in 2022 and is expected to reach USD 3.42 billion by 2030, registering a CAGR of 6.6% during the forecast period of 2023-2030

Market Overview

The impregnating resins market has witnessed steady growth over the past decade, driven by several factors. Firstly, the rising demand for electrical and electronic components across industries such as automotive, aerospace, and energy has propelled the need for efficient and reliable insulation materials. Impregnating resins offer a cost-effective solution for manufacturers looking to improve the performance and durability of their products.

Furthermore, environmental concerns have led to increased adoption of impregnating resins, as they are often more sustainable and environmentally friendly than alternative materials. Many resins are low in volatile organic compounds (VOCs) and are compliant with environmental regulations, making them an attractive choice for conscious consumers and manufacturers.

Key Growth Drivers

Electrification Trends: The ongoing shift toward electrification in automotive and transportation sectors has created a surge in demand for impregnating resins. Electric vehicles (EVs) rely heavily on electronic components and batteries, all of which require robust insulation and protection.

Renewable Energy: With the growing emphasis on renewable energy sources, impregnating resins are used extensively in wind turbine generators and solar panels. These resins enhance the durability of these systems, making them more reliable and sustainable.

Miniaturization of Electronics: The electronics industry continues to trend toward miniaturization. Impregnating resins play a critical role in protecting and insulating these smaller, more delicate components from external factors.

Innovations in Impregnating Resins

The impregnating resins market has witnessed a wave of innovations aimed at improving performance, reducing environmental impact, and expanding applications. Some notable advancements include:

Biobased Resins: The development of biobased impregnating resins, derived from renewable sources like soybean oil or castor oil, offers a more sustainable alternative to traditional petroleum-based resins. These resins have lower carbon footprints and are gaining popularity in eco-conscious industries.

Nanotechnology: Incorporating nanomaterials into impregnating resins has led to enhanced mechanical and electrical properties. Nanoparticles can reinforce the resin matrix, making it more resistant to wear and tear.

Low-VOC Formulations: Manufacturers are investing in research to develop low-VOC impregnating resins, aligning with stricter environmental regulations. These resins emit fewer harmful chemicals during the curing process.

Smart Coatings: Some impregnating resins are now equipped with sensors and self-healing properties. These smart coatings can detect damage and automatically repair minor cracks, extending the lifespan of protected components.

Emerging Opportunities

As industries continue to evolve, new opportunities are emerging in the impregnating resins market:

Advanced Electronics: The demand for impregnating resins in advanced electronics, such as 5G infrastructure and IoT devices, is expected to grow significantly as these technologies become more widespread.

Electric Grid Upgrades: Aging electrical infrastructure requires upgrades, creating opportunities for impregnating resin manufacturers to supply materials for insulating and protecting critical components.

Medical Devices: The medical device industry requires high-performance materials with biocompatibility. Impregnating resins can find applications in this sector for coating and protecting sensitive medical electronics.

Conclusion

The impregnating resins market is poised for continued growth, driven by the increasing demand for reliable electrical and electronic components across various industries. Innovations in materials and manufacturing processes are enabling the development of more sustainable, high-performance resins, opening doors to new applications and markets. As technology evolves and environmental concerns intensify, impregnating resins will remain a vital element in ensuring the durability and reliability of critical components in our modern world.

About Market Research Future:

Market Research Future (MRFR) is a global market research company that takes pride in its services, offering a complete and accurate analysis of diverse markets and consumers worldwide. Market Research Future has the distinguished objective of providing optimal quality research and granular research to clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help answer your most important questions.

Contact:

Market Research Future (Part of Wantstats Research and Media Private Limited)

99 Hudson Street, 5Th Floor

New York, NY 10013

United States of America

+1 628 258 0071 (US)

+44 2035 002 764 (UK)

Email: [email protected]

Website: https://www.marketresearchfuture.com