Control Towers in Supply Chain Management: A Comprehensive Guide

Introduction:

In the complex and dynamic world of modern supply chain management, staying ahead of the curve is crucial for businesses seeking efficiency, resilience, and competitive advantage. The concept of a “control tower” has emerged as a powerful solution to navigate this intricate landscape. A supply chain control tower serves as the nerve centre of your operations, providing real-time visibility, data-driven insights, and the ability to make proactive decisions. In this comprehensive guide, we will delve into the fundamental principles, strategies, and benefits of control towers in supply chain management.

What is Supply Chain Management?

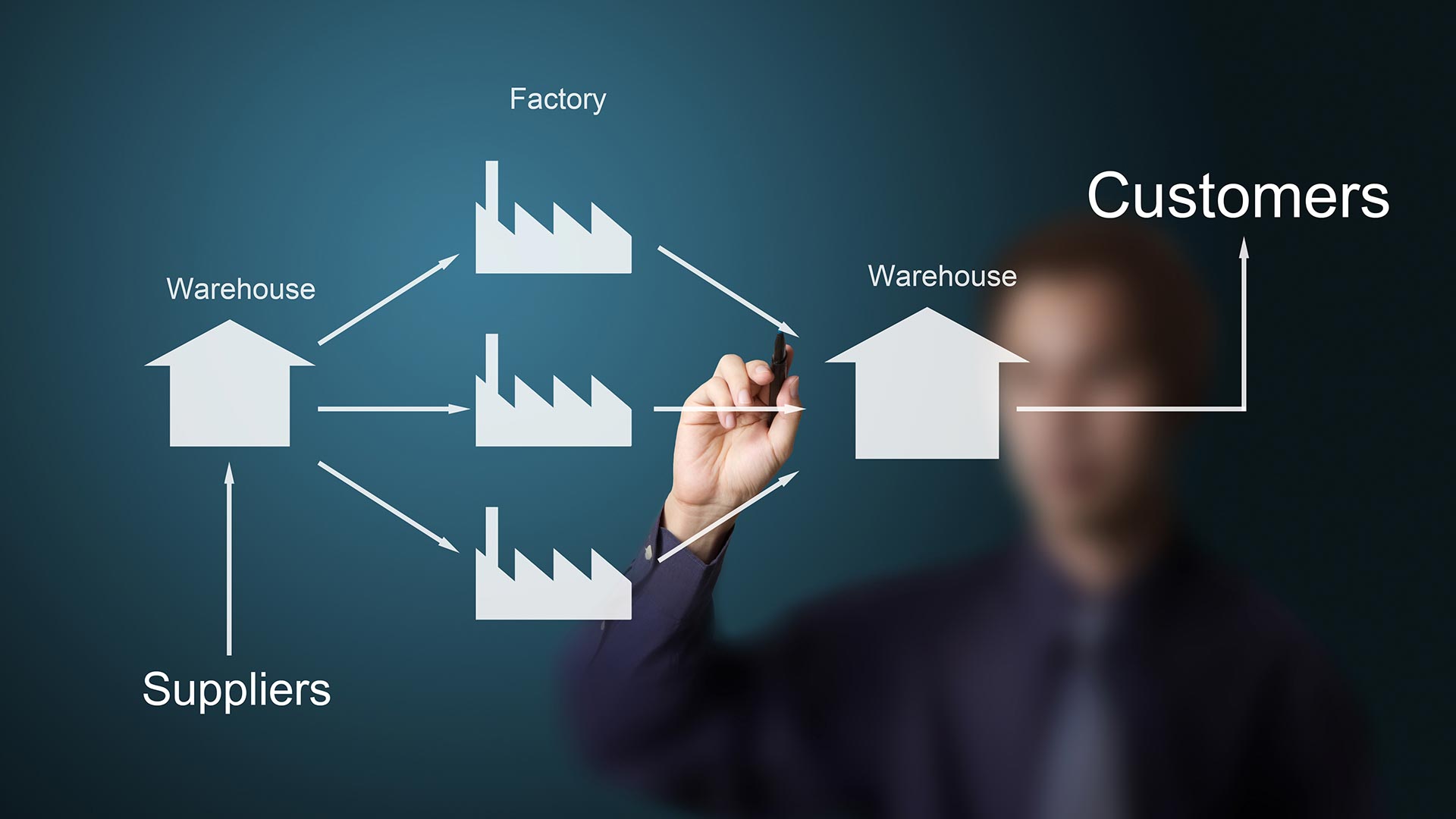

Supply chain management (SCM) is the process of planning, implementing, and controlling the flow of goods, services, information, and finances as they move from the supplier to the manufacturer to the wholesaler to the retailer and finally to the end consumer. The primary goal of supply chain management is to maximize efficiency and minimize costs while ensuring that products or services are delivered to the end customer in a timely manner and with the desired quality.

Components of Supply Chain Management:

Planning:

- This involves forecasting demand, setting inventory levels, and developing strategies for sourcing, production, and distribution.

Sourcing:

- Selecting and managing suppliers, negotiating contracts, and ensuring a stable and efficient supply of materials or services.

Manufacturing:

- Managing the production process to meet demand efficiently while maintaining quality standards.

Inventory Management:

- Balancing the costs of holding inventory against the costs of stockouts or shortages.

Logistics and Transportation: Planning and optimizing the movement of goods, including selecting transportation modes, routes, and carriers.

Distribution:

- Ensuring that products reach their intended destinations, which may involve warehousing, order fulfilment, and last-mile delivery.

Information Systems:

- Using technology and data analytics to monitor and manage the supply chain, track inventory, and make informed decisions.

Strategies of Supply Chain Management:

Supplier Relationship Management (SRM):

- Cultivate strong relationships with suppliers to ensure a steady and reliable source of materials or products. Collaborate with them to improve quality, reduce costs, and enhance innovation.

Demand Forecasting:

- Use historical data, market trends, and customer insights to predict future demand accurately. This helps in planning production, inventory, and distribution more effectively.

Logistics and Transportation Optimization:

- Select the most cost-effective and efficient transportation and logistics solutions. This may include using various modes of transportation, route optimization, and consolidating shipments.

Supplier Diversification:

- Avoid relying too heavily on a single supplier or region. Diversify your supplier base to reduce the risk of disruptions in the supply chain.

Lean Supply Chain:

- Apply lean principles to eliminate waste, reduce lead times, and improve overall efficiency. Lean techniques like Kanban and continuous improvement are often used.

Technology Integration:

- Leverage technology such as Enterprise Resource Planning (ERP) systems, Warehouse Management Systems (WMS), and Advanced Planning and Scheduling (APS) software to streamline operations and improve visibility.

Benefits of Control Tower Supply Chain Management:

Cost Reduction:

- Improved inventory management helps reduce carrying costs and eliminates overstocking or stockouts.

- Efficient transportation and logistics management can lead to lower shipping and handling costs.

- Better supplier relationships can result in negotiated lower prices and discounts.

Enhanced Efficiency:

- Streamlined processes and workflows reduce lead times, resulting in faster product delivery.

- Accurate demand forecasting minimizes the risk of excess inventory.

- Just-in-time (JIT) inventory systems reduce waste and improve resource allocation.

Improved Customer Service:

- Faster order processing and delivery times lead to higher customer satisfaction.

- Real-time tracking and visibility into the supply chain enable better communication with customers.

Risk Mitigation:

- Supply chain management helps identify and mitigate risks, such as supplier disruptions, natural disasters, or geopolitical issues.

- Diversifying suppliers and sourcing options can reduce dependency on a single source.

Increased Competitiveness:

- Optimized supply chains enable companies to be more competitive in pricing and product availability.

- Better responsiveness to market changes and customer demands can give a competitive edge.

Better Decision-Making:

- Data analytics and reporting tools provide insights for data-driven decision-making.

- Improved visibility into the supply chain helps identify areas for improvement and optimization.

Sustainability and CSR:

- Supply chain management can support sustainability efforts by reducing waste, energy consumption, and carbon emissions.

- Ethical sourcing and responsible practices contribute to corporate social responsibility (CSR) initiatives.

Compliance and Quality Control:

- Ensuring compliance with regulations and standards is easier with effective supply chain management.

- Quality control measures can be implemented and monitored throughout the supply chain.

FAQs: Control Towers in Supply Chain Management

Q.1 What is a Supply Chain Control Tower?

A1: A Supply Chain Control Tower is a centralized platform or technology solution that provides end-to-end visibility and control over all aspects of a supply chain.

Q.2 Why is Supply Chain Visibility Important?

A2: Supply chain visibility is crucial because it allows businesses to monitor and manage their supply chain operations more effectively, leading to better decision-making, reduced risks, and improved customer satisfaction.

Q.3 What Information Does a Control Tower Provide?

A3: Control Towers typically provide real-time data on inventory levels, transportation status, order fulfilment, and other key supply chain metrics.

Q.4 How Does a Control Tower Improve Supply Chain Efficiency?

A4: Control Towers use data analytics and automation to streamline processes, reduce bottlenecks, and optimise routes, which leads to increased efficiency and cost savings.

Q.5 What Are the Key Benefits of Implementing a Control Tower?

A5: Benefits include improved visibility, reduced lead times, lower operational costs, enhanced customer service, and better supply chain risk management.

Conclusion:

Control Towers have emerged as indispensable tools in modern Supply Chain Management. They provide organisations with real-time visibility, proactive monitoring, and data-driven decision-making capabilities, ultimately leading to improved operational efficiency, cost reduction, and enhanced customer satisfaction. By centralising information, automating processes, and fostering collaboration among stakeholders, Control Towers enable businesses to navigate the complexities of today’s global supply chains more effectively. As a leading provider of supply chain solutions, QodeNext can help you design, implement, and optimize a control tower solution.